There are many different types of packaging available on the market, making it difficult to choose the best one for your company’s needs. One of the most common packaging materials is the corrugated box.

Corrugated box ups are available in a variety of sizes, lengths, and thicknesses that can be custom-tailored to fit your company’s needs. They are also relatively inexpensive, making them an affordable option for smaller packaging needs. However, there are a few drawbacks to using acme corrugated boxes.

This article will highlight the good, the bad, and the ugly of using corrugated boxes wholesale for your packaging program.

Contents

What is a corrugated box?

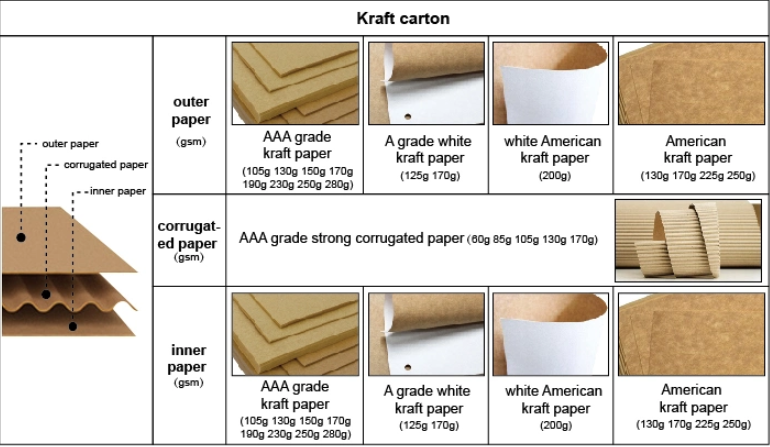

A corrugated box is a rigid, lightweight polyethylene packaging container made up of multiple layers. The corrugated box consists of three components: the inner layer, an outer layer, and a paperboard liner.

The inner layer is the actual packaging material that is used to contain your product. It consists of paperboard, cardboard, or plastic-coated paper (depending on the type of corrugated box you are using).

This inner layer is molded into multiple box layers to form the corrugated box. The outer layer serves as an additional barrier for your product and also provides additional strength for your packaging materials.

This outer layer is usually made up of a thick polyethylene film or a hard plastic sheet with a fiberglass reinforcement core to make it more durable.

The final component is the paperboard liner that serves as a protective coating for your product’s contents and also provides additional strength for your corrugated boxes.

Corrugated box manufacturing process?

How do corrugated box manufacturers make these boxes? The corrugated box manufacturing process is fairly straightforward.

It all starts with the corrugated box design. Here, you will be provided with a corrugated box design (either from you or from a third party).

This design will include the box dimensions and the number of layers of your box. You will then have to create your corrugated boxes at the same time that you are designing them.

For this, a corrugated machine is used. This type of machine is made to make multiple boxes at once, and it includes many moving parts that allow it to produce different boxes at different rates.

This machine can be operated in two ways: manually or automatically. Manual operation is done by loading each layer into the machine manually and then connecting them with an automatic stacking device that allows for the automatic stacking of multiple layers into one large box.

The automatic operation uses a conveyor belt system that automatically connects all the layers as they are being produced.

The final step in making a corrugated box is cutting it out of the formed layer (which was previously cut out by a cutting machine).

This is done by using a corrugating machine that cuts out the shape of the box from the formed layer. This machine is made to work with multiple layers.

You can find corrugated box manufacturers near me for a detailed step-by-step explanation of how they do the whole process.

Corrugated box vs cardboard box: What is the difference?

The main difference between corrugated boxes and cardboard boxes is that corrugated boxes are more durable because they can be folded multiple times to make them more compact.

They also allow for more efficient use of space, so they are perfect to ship items that have a larger volume than what would fit in a regular cardboard box.

Corrugated boxes cost more than cardboard, but they are better quality than regular cardboard boxes.

They can be used to ship many different items, and they will hold up much better in shipping situations.

Corrugated box specifications

Like other products, you should know the specs of the corrugated box when purchasing. Some of these specs include;

-Dimension: This refers to the size of the corrugated box. It is usually measured in inches, but it can also be measured in centimeters or millimeters. The dimensions can be length and height width among others.

-Weight: This refers to the weight of the box. The weight is usually measured in pounds, but it can also be measured in kilograms or grams.

-Printable Area: This refers to the area of the box that can be printed on and cut out by a cutting machine.

-Corrugate: This refers to the material used in making the box. It can be made from different materials such as paper, polystyrene, jute, and many others.

Is the higher the hardness of the corrugated box the better?

Many people believe that the harder the corrugated box, the better the quality. In fact, this statement is incorrect. The relationship between them is more than a simple proportional relationship. Corrugated box manufacturers will share with you the relationship between the hardness and quality of corrugated boxes.

The relationship between corrugated carton hardness and carton quality

1. How to judge the quality of corrugated cartons

Whether a carton is qualified or not depends on three indicators. The first is the fracture strength of the carton. Fracture strength is the uniform pressure value that the cardboard can withstand per unit area. The second is the compressive strength of the carton, which is the ability of the corrugated box to withstand pressure parallel to the direction of the corrugation. Then comes the compressive strength of the corrugated box. Compressive strength is the force that the box can withstand when the force generated by a uniform increase in displacement compresses the box. These three points are the criteria that really determine the quality of a cardboard box.

2. Relationship between the hardness of a corrugated box and the quality of the box

The hardness of a corrugated carton is not necessarily related to the quality of the carton. Corrugated boxes are made of a variety of materials. Corrugated boxes made with different materials will have different hardnesses and will have different uses. This cannot be killed in one shot. If the hardness is low, the quality of the carton will be poor. We need to choose the right paper to make the carton according to the actual use.

Suneco Packaging Co., Ltd. specializes in all types custom logo corrugated box, a variety of corrugated carton paper products, heavy duty box suitable for various industries, such as product packaging and transportation purposes, we provide excellent service, good products for the majority of consumers!

Corrugated Packing Box Types

There are different corrugated box types that you can find in the market today. Some of these types include;

-Whiteboard: This is a corrugated box that is designed for holding whiteboards on it. It has a special area on it that holds the whiteboard securely. It also has an area on top that can be used to hang up the whiteboard when not in use.

-Folding Corrugated Boxes: These are corrugated boxes that are designed for storing items like clothes or other things inside them. They are generally flat with a top handle.

-Acme corrugated box: This is a corrugated box that is designed for holding small items like brochures, leaflets, or other promotional items. It has a handle on top and it is generally flat.

-Cardboard Corrugated Boxes: As the name suggests, these boxes feature a heavy presence of cardboard material. They are strong and tend to be lightweight and hence easily portable.

-Corrugated carton box: Probably you have used carton boxes for different applications. Would you like something that is similar to the cartons but still offers an array of other advantages? Talk to a corrugated box supplier for a 5ply corrugated box.

Corrugated metal planter box: Do you need something stronger, rugged, and durable? a corrugated metal planter box should be your ideal choice. These boxes are strong enough to carry heavy loads and can be reused for different purposes.

How to test the protective properties of corrugated box?

Corrugated cardboard boxes are often used as packaging materials in our daily lives, and are usually used by logistics companies when packaging products. If a corrugated box is of poor quality, it is easy to break it. What tests can be used to measure the protective performance of a qualified corrugated box? Here, follow me to learn more about it! I hope this will help you.

1. Carton pressure test

Carton pressure test is a basic test of carton performance, which can determine the compression capacity of the carton under different conditions. The equipment used for carton pressure test is a special pressure tester. The upper and lower pressure plate area of the test machine is generally 1.5mX1.5m or 1mX1m. One of the two pressure plates is the support plate, whose position can be adjusted according to the size of the sample to make it suitable, and then the height is fixed to the carton. The other is the compression plate, which can be slid along the guide plate to apply pressure to the sample.

2、Carton drop test

Carton drop test measures the performance of the carton and the cushioning effect of the carton structure, and is suitable for total weight less than 150 kg or smaller packaging volume. The equipment used in the tester is relatively simple, and a hook and drop tester or spreader tester can be used.

3、Oblique angle impact performance

For heavy or bulky packaging (for example, the weight of more than 150kg of packaging), you can use the bevel impact test to test the impact resistance of packaging and items, the bevel impact test imitates the powerful impact generated by trains, cars starting, braking and going downhill.

This test also provides similar experiments for various impact forces caused during transportation (e.g., through conveyors, lifting, unloading, etc.). The test device is a crash test machine consisting of a chute, a skid, and a baffle.

4、Spray test

According to the specified time and the amount of water sprayed and the water resistance of the carton and the protection of the carton, the corrugated carton under the specified conditions of the spray has been detected to the content.

Where to buy corrugated boxes wholesale?

The first thing that will come into your mind is getting corrugated boxes near me. You don’t want to strain when it comes to buying a simple corrugated carton box.

The whole secret lies in choosing reliable corrugated box manufacturers and suppliers. This is the only way that you will end up with a quality box that will serve its purpose for ages.

Are you buying corrugated boxes wholesale? You will still use this technique of finding the manufacturer or supplier directly.

Conclusion

Now that you know the basics of corrugated boxes, what next? You need to go ahead and buy one.

Just like any other product, one should look into the quality of the corrugated packing boxes before buying them. The box is not just made out of corrugated material but it should be strong and sturdy as well.

By Sofier Ju

By Sofier Ju