Contents

Eco-Friendly Full Degradable Bio-Resin Pbat

PBAT

Product Description

PBAT is a fully biodegradable material with high tensile launched by our company. The main component is fully biodegradable polymer blends.

PBAT Technical Properties

1. Material Technical Properties

| Property | Unit | Test Method | Value | |

| Fundamental characteristics | Density | g/cm3 | ISO 1183 | 1.24±0.02 |

| Hardness | D | ASTM-D2240 | 50±5 | |

| Acid value | mol/t | ISO2114 | 35±5 | |

| Thermal property | Melt flow rate MFR190ºC, 2.16kg | g/10min | ISO 1133 | ≤5 |

| Melting range | ºC | ASTM-D3418 | 95-135 | |

| Vitrification temperature | ºC | ASTM-D3418 | -30 | |

| Thermal decomposition temperature | ºC | ASTM-D6371 | 370 | |

| Vicat softening point/A50 | ºC | ISO306 | 90 | |

| Mechanical properties | Young’s modulus | Mpa | ISO527 | 75±5 |

| tensile strength | Mpa | ISO527 | 20±2 | |

| Tensile Elongation Break | % | ISO527 | 600±50 | |

| Notched Impact Strength | KJ/m2 | ISO179 | 21 |

Note:

- Storage:

During transportation and storage, the temperature may not exceed 70 oC at any time. Storage time of unopened bags may not surpass 12 months at room temperature (23 oC) .

- For granules: 12 months from the date of loading under proper storage conditions. If customers need to open bags and use them partially, once opened they recommend to seal again properly and using them within 3 months.

- For film: we suggest customers use it within 6 months.

- Packaging:

- in 25kg bag, liner: PE/Alu

- in 750kg bag/octabin, liner: PE/Alu (3 )in 1.2t bag/octabin, liner: PE/Alu

PBAT Processing Instruction

- Extruder selection:

A double screw extruder is applicable, the length-diameter ratio of the film blowing machine should be ≥ 30.

- Pre-cleaning:

Washing the machine by using PBAT under temperature 160± 10oC.

- Pre-drying:

PBAT doesn’t need pre-drying. (Under the condition package is not damaged). If the package is damaged, then the material needs to be dried for 4hours under 65ºC.

- Processing data:

If PBAT blending with PLA, we suggest each heating section of extruder heat gradually increase from 155 oC to 190ºC, rotating speed≥250RPM; If PBAT blending with PBS, we suggest each heating section of extruder heat gradually increase from 115 oC to 155ºC, rotating speed≥180RPM; If PBAT blending with starch, we suggest each heating section of extruder heat

gradually increase from 115 oC to 140ºC, with a rotating speed of≥180RPM; it can be adjusted according to the actual situation and output.

- Residence time:

The residence time for PBAT in the extruder should remain less than 5 minutes. The extruded material will look darker or yellow with a long residence time. If the extruded material becomes brittle, it may be caused by resin degradation or filler carbonization.

- Remark

When MFR is equal, PBAT has good consistency with other biodegradable materials, such as PBS, PLA, starch, etc. We suggest adding a suitable chain extender and solubilizer when producing PBAT/PLA compound, we suggest adding a suitable lubricating agent when producing PBAT/starch or PBAT/inorganic fillers.

Eco-Friendly Full Degradable Bio-Resin PBAT: The Future of Sustainable Plastic

As concerns about plastic waste and environmental sustainability continue to grow, researchers and manufacturers are exploring new materials and technologies to reduce the impact of plastic products on the environment. One such material that has gained attention in recent years is PBAT, a biodegradable bio-resin that has the potential to revolutionize the plastics industry.

PBAT, or polybutylene adipate terephthalate, is a biodegradable plastic that is made from renewable resources such as cornstarch and sugarcane. Unlike traditional plastics, which can take hundreds of years to decompose, PBAT is designed to break down naturally in a matter of months or years, depending on the conditions. This makes it a promising alternative for applications where traditional plastics are not suitable, such as food packaging, agricultural films, and other disposable products.

What is PBAT?

PBAT is a thermoplastic polyester that is produced by combining adipic acid, terephthalic acid, and butanediol. The resulting polymer is a flexible, transparent, and biodegradable plastic that has similar properties to traditional polyethylene (PE) or polypropylene (PP) plastics. However, unlike these traditional plastics, PBAT can be degraded by microorganisms such as bacteria, fungi, and algae, under the right conditions.

One of the key advantages of PBAT is that it can be produced from renewable resources such as cornstarch or sugarcane, which reduces the reliance on fossil fuels and other non-renewable resources. This makes PBAT a more sustainable and eco-friendly option for plastic products, especially for applications where single-use plastics are common.

Why is PBAT a Game-Changer for the Plastics Industry?

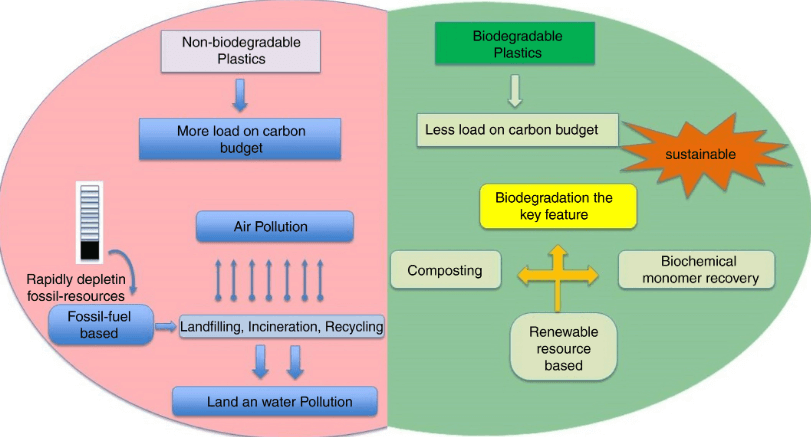

PBAT is a game-changer for the plastics industry because it offers a solution to the problem of plastic waste and environmental pollution. Traditional plastics such as PE and PP are not biodegradable, which means they can persist in the environment for hundreds of years, causing damage to ecosystems and wildlife.

PBAT, on the other hand, is designed to break down naturally in the environment, reducing the impact of plastic waste on the environment. This means that products made from PBAT, such as food packaging, shopping bags, and other disposable items, can be disposed of safely without causing long-term harm to the environment.

Another advantage of PBAT is that it can be recycled along with other biodegradable materials, such as food waste and yard waste, in industrial composting facilities. This allows for the production of high-quality compost that can be used to enrich soil and support plant growth.

The Future of PBAT

PBAT is still a relatively new material in the plastics industry, but it has the potential to become a widely used and versatile material for a range of applications. Researchers and manufacturers are exploring new ways to improve the performance and properties of PBAT, such as its strength, durability, and flexibility, to make it more suitable for a range of applications.

One area where PBAT is particularly promising is in the production of agricultural films, such as mulch films and greenhouse films. These films are used to protect crops from pests, weeds, and weather conditions, but they are often made from non-biodegradable plastics that can contaminate soil and water sources. PBAT films offer a more sustainable and eco-friendly alternative that can reduce the impact of agriculture on the environment.

Eco-Friendly PBAT: The Full Degradable Bio-Resin Solution

As we become more aware of the impact that we have on the environment, we are constantly searching for ways to reduce our carbon footprint. One area that has been receiving a lot of attention lately is the use of biodegradable materials in manufacturing. In particular, the development of eco-friendly full degradable bio-resin PBAT has been gaining traction as a sustainable alternative to traditional plastics.

PBAT, or polybutylene adipate terephthalate, is a biodegradable polyester that is derived from renewable resources such as corn starch or sugarcane. It is also fully compostable, meaning that it can break down into natural elements without leaving any toxic residue. This makes it an ideal material for a wide range of applications, from packaging to disposable cutlery and even clothing.

The benefits of using PBAT are clear. Not only does it reduce our reliance on non-renewable resources, but it also helps to reduce the amount of waste that ends up in landfills and oceans. As more companies begin to adopt PBAT as their material of choice, we can look forward to a future where sustainability is at the forefront of every industry.

Understanding Bio-Resin Pbat

Bio-resin Pbat is a type of biodegradable plastic that is made from a blend of polybutylene adipate terephthalate (Pbat) and other natural materials. It is an eco-friendly alternative to traditional petroleum-based plastics, which can take hundreds of years to decompose in landfills and contribute to environmental pollution.

One of the key benefits of bio-resin Pbat is that it is fully degradable, meaning it can break down into natural elements such as water, carbon dioxide, and biomass within a relatively short period of time. This makes it an ideal material for use in a variety of applications, including food packaging, shopping bags, and other disposable products.

Another advantage of bio-resin Pbat is that it is derived from renewable resources, such as corn starch, sugarcane, and other plant-based materials. This reduces our reliance on finite fossil fuels and helps to promote a more sustainable future.

At the same time, it is important to note that bio-resin Pbat is not a perfect solution to our environmental challenges. While it is biodegradable, it still requires energy and resources to produce and transport, and it may not be suitable for all applications. Additionally, it is important to ensure that bio-resin Pbat is disposed of properly to ensure that it can break down as intended.

In conclusion, bio-resin Pbat is a promising material that offers a number of environmental benefits over traditional plastics. By understanding its properties and limitations, we can work to develop more sustainable solutions that help to protect our planet for future generations.

Eco-Friendly Nature of Bio-Resin Pbat

Bio-resin PBAT is a type of biodegradable plastic that is becoming increasingly popular due to its eco-friendliness. At our company, we are proud to offer this sustainable alternative to traditional plastics, and we believe it is important for consumers to understand the benefits of using bio-resin PBAT.

One of the main advantages of bio-resin PBAT is that it is fully degradable. This means that when it is disposed of properly, it will break down naturally and not harm the environment. Unlike traditional plastics, which can take hundreds of years to decompose, bio-resin PBAT can be broken down in a matter of months. It is also non-toxic, so it won’t release harmful chemicals into the environment as it degrades.

Another benefit of bio-resin PBAT is that it is made from renewable resources. Traditional plastics are made from non-renewable resources like petroleum, which is a finite resource. Bio-resin PBAT, on the other hand, is made from plant-based materials like cornstarch and sugarcane, which can be grown and harvested repeatedly. This makes bio-resin PBAT a more sustainable choice for the future.

Finally, bio-resin PBAT has a lower carbon footprint than traditional plastics. The production of traditional plastics is a major contributor to greenhouse gas emissions, while the production of bio-resin PBAT produces fewer emissions. This makes bio-resin PBAT a more environmentally friendly option overall.

Overall, we believe that bio-resin PBAT is an excellent choice for those who want to reduce their environmental impact. It is fully degradable, made from renewable resources, and has a lower carbon footprint than traditional plastics. We are excited to be a part of the movement towards more sustainable materials and hope that more consumers will choose bio-resin PBAT in the future.

Full Degradability of Bio-Resin Pbat

Our Eco-Friendly Full Degradable Bio-Resin Pbat is a revolutionary product that offers a sustainable solution for plastic waste. One of the key features of our Bio-Resin Pbat is its full degradability.

Unlike traditional plastic, which can take hundreds of years to degrade, our Bio-Resin Pbat fully degrades within 180 days in a composting environment. This means that our product does not contribute to the buildup of plastic waste in landfills or oceans.

Our Bio-Resin Pbat is made from renewable resources such as corn starch and sugarcane. This makes it a sustainable alternative to petroleum-based plastics. Additionally, our product does not emit harmful gases during the degradation process, making it safe for the environment.

We have conducted extensive testing to ensure the full degradability of our Bio-Resin Pbat. Our product has been certified by various organizations, including the Biodegradable Products Institute (BPI) and the European Bioplastics Association (EUBP).

In summary, our Eco-Friendly Full Degradable Bio-Resin Pbat offers a sustainable solution for plastic waste. With its full degradability, made possible by the use of renewable resources, our product does not contribute to the buildup of plastic waste. We are confident in the quality and effectiveness of our product, as demonstrated by our certifications from reputable organizations.

Production Process of Bio-Resin Pbat

Our company produces eco-friendly full degradable bio-resin PBAT using a unique process that involves several steps.

First, we start by mixing three main components: polybutylene adipate terephthalate (PBAT), starch, and glycerol. PBAT is a biodegradable polyester that is derived from renewable resources such as cornstarch, while starch is a natural polymer that is extracted from plants. Glycerol is a plasticizer that helps to improve the flexibility and strength of the final product.

After mixing the components, the resulting mixture is then melted and extruded into pellets. The pellets are then cooled and stored until they are ready for use.

When producing products using our bio-resin PBAT, the pellets are melted again and molded into the desired shape using injection molding or extrusion. The final product is then cooled and packaged for distribution.

Our production process is designed to minimize waste and reduce the environmental impact of our products. We carefully monitor the production process to ensure that we are using the most sustainable and eco-friendly methods possible.

Overall, our production process for bio-resin PBAT is efficient, sustainable, and environmentally friendly. We are committed to producing high-quality, eco-friendly products that meet the needs of our customers while also protecting the planet.

Applications of Bio-Resin Pbat

Bio-resin Pbat is a versatile and eco-friendly material that can be used in a variety of applications. Here are some examples of how it can be used:

- Packaging: Bio-resin Pbat is an excellent alternative to traditional plastic packaging. It can be used for food packaging, shipping materials, and more. It is also compostable, which means it won’t contribute to the growing plastic waste problem.

- Agriculture: Bio-resin Pbat can be used in agriculture as a biodegradable mulch film. This film helps to retain moisture in the soil, suppress weeds, and regulate soil temperature. It is also an excellent alternative to traditional plastic mulch films, which can take hundreds of years to degrade.

- Textiles: Bio-resin Pbat can be used to create eco-friendly textiles. It can be blended with other natural fibers such as cotton or hemp to create fabrics that are both durable and sustainable.

- Disposable products: Bio-resin Pbat can be used to create a variety of disposable products such as straws, cutlery, and plates. These products are perfect for events or businesses that need to use disposable items but want to reduce their environmental impact.

- Construction: Bio-resin Pbat can be used in construction as a biodegradable alternative to traditional plastic materials. It can be used to create insulation, roofing materials, and more.

Overall, bio-resin Pbat is a versatile and eco-friendly material that can be used in a variety of applications. Its ability to biodegrade makes it an excellent alternative to traditional plastic materials that can take hundreds of years to degrade.

Benefits and Limitations of Bio-Resin Pbat

Bio-resin PBAT offers several benefits over traditional petroleum-based plastics.

Firstly, it is a renewable resource and is derived from natural materials such as corn starch, potato starch, and tapioca roots. This makes it a more sustainable option compared to petroleum-based plastics, which are non-renewable and contribute to environmental degradation.

Secondly, bio-resin PBAT is fully biodegradable and compostable, meaning it can be broken down by microorganisms into natural elements such as carbon dioxide, water, and biomass. This reduces the amount of plastic waste in landfills and the environment, and also reduces the carbon footprint associated with plastic production.

Thirdly, bio-resin PBAT has similar mechanical and physical properties to traditional plastics, making it a viable alternative for various applications such as packaging, bags, and disposable cutlery.

However, there are also some limitations to using bio-resin PBAT.

One major limitation is its higher cost compared to traditional plastics. This is due to the higher cost of producing and processing natural materials compared to petroleum-based materials.

Another limitation is its lower durability and shelf life. Bio-resin PBAT is more susceptible to degradation from heat, moisture, and UV radiation, which can affect its mechanical and physical properties over time.

Overall, bio-resin PBAT is a promising alternative to traditional plastics, but it is important to weigh the benefits and limitations before choosing it for a specific application.

Future Perspectives of Bio-Resin Pbat

As we continue to prioritize sustainability and eco-friendliness, we see a bright future for Bio-Resin Pbat. With its unique properties and biodegradability, it has the potential to replace traditional petroleum-based plastics in a wide range of applications.

One area where Bio-Resin Pbat shows great promise is in the packaging industry. As consumers become more conscious of the impact of their purchases on the environment, demand for sustainable packaging solutions is on the rise. Bio-Resin Pbat offers a viable alternative to traditional plastics, with the added benefit of being fully biodegradable.

Another area where Bio-Resin Pbat can make a significant impact is in agriculture. The use of traditional plastics in agriculture can have negative effects on soil health and contribute to pollution. Bio-Resin Pbat, on the other hand, is fully biodegradable and can be used in a variety of applications such as mulch films, seedling trays, and irrigation tubing.

As the technology behind Bio-Resin Pbat continues to evolve, we can expect to see even more applications for this innovative material. With advancements in processing techniques and improvements in the quality of raw materials, Bio-Resin Pbat has the potential to become a truly versatile and sustainable alternative to traditional plastics.

Overall, we believe that Bio-Resin Pbat has a bright future ahead of it. Its unique properties and biodegradability make it an attractive option for a wide range of applications, and we look forward to seeing how this innovative material continues to evolve and make a positive impact on our planet.

PBAT is a biodegradable bio-resin that has the potential to revolutionize the plastics industry and reduce the impact of plastic waste on the environment. Using renewable resources to produce a plastic that is biodegradable.

By Sofier Ju

By Sofier Ju