In the dynamic world of agricultural commerce, the packaging of produce plays a pivotal role in ensuring its safe transit and presentation.

Among the diverse array of crops, sweet potatoes hold a special place, revered for their versatility and nutritional value.

Behind the scenes of this thriving industry lies the realm of sweet potato carton manufacturing, where precision and ingenuity converge to create containers that not only protect the produce but also serve as ambassadors of quality and brand identity.

Let us explore the intricacies of manufacturing sweet potato cartons, from production to distribution.

1. Understanding the Product

Before delving into the manufacturing process, it is essential to understand the specifications of the product. Sweet potato cartons, with dimensions of 40x30x14cm and a carrying weight of 6kg, must be sturdy and stackable. These features are vital to ensure the safe transportation and storage of the delicate produce within.

2. Design Considerations

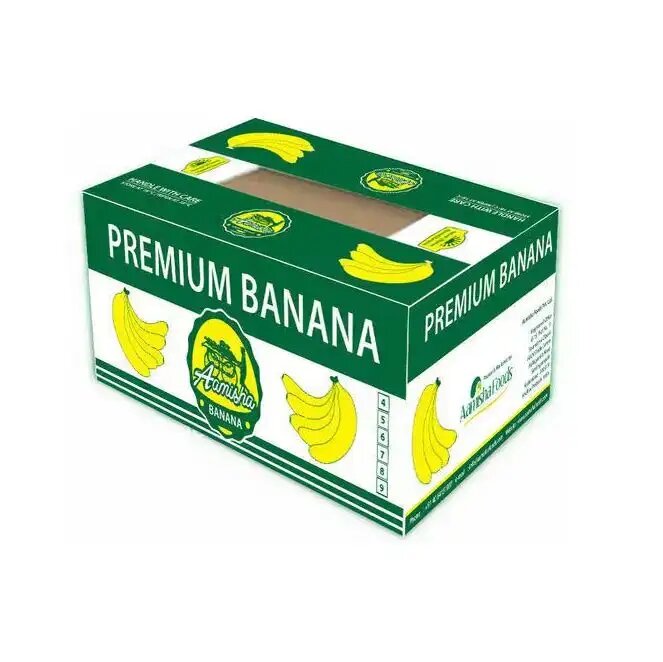

Design plays a crucial role in the branding and marketing of sweet potato cartons. Our company, committed to excellence, envisions cartons adorned with our signature colors – Green: #041502 and Gold: #b78628 – reflecting our dedication to quality and sustainability. Embellished with our logo, these cartons serve as a canvas for our brand identity. Additionally, a designated space on the rear end allows for the affixation of import specification labels, ensuring compliance with regulatory requirements.

3. Manufacturing Process

The journey of crafting sweet potato cartons begins in the realm of manufacturing. Partnering with reputable factories equipped with advanced technology and skilled personnel, we ensure precision and quality at every stage of production. These factories, selected through stringent evaluation processes, adhere to international standards, guaranteeing consistency and reliability in our products.

4. Sourcing Raw Materials

The quality of sweet potato cartons hinges on the materials used in their construction. We prioritize sustainability, sourcing eco-friendly cardboard and inks that align with our commitment to environmental stewardship. Collaborating with trusted suppliers, we secure a steady supply of high-quality raw materials, essential for crafting cartons that meet both functional and ethical standards.

5. Packaging and Distribution

Once the sweet potato cartons are manufactured to perfection, they undergo meticulous packaging processes to ensure their safe transit to their destination. Typically, 150 boxes are arranged on a pallet, optimizing space and minimizing the risk of damage during transportation. These pallets, laden with sweet potato cartons, are then shipped via container to Europe, where they will be distributed to retailers and consumers.

6. Cost and Pricing

While maintaining quality is paramount, cost considerations play a significant role in the manufacturing process. By optimizing production efficiency, sourcing materials strategically, and streamlining logistics, we strive to offer competitive pricing without compromising on quality. Transparent pricing policies ensure that our clients receive value for their investment, fostering long-term partnerships based on trust and mutual benefit.

Conclusion

In conclusion, the manufacturing of sweet potato cartons is a multifaceted process that requires meticulous attention to detail, from design to distribution.

By prioritizing quality, sustainability, and efficiency, we endeavor to create cartons that not only protect the produce within but also reflect our commitment to excellence and environmental responsibility.

As these cartons journey across continents, bearing the bounty of sweet potatoes within, they stand as testaments to the craftsmanship and innovation of the manufacturing industry.

By Sofier Ju

By Sofier Ju