Packaging boxes are necessary for any product supplier or buyer. However, different boxes have varying costs in the market. Below you will find a simple buying guide.

How do you know packaging box pricing? That is the first question for anyone with packaging needs. However, the answer to the question is not as simple as most will think. The packaging industry often consists of many non-transparent individuals.

Thus, getting the standard cost estimates may be time-consuming and challenging. Also, there is a high risk of a dramatic increase in price if you fail to ask the right questions. Therefore, you must know all the necessary details regarding price to avoid misleading.

You should also note that some packaging companies may be reluctant to give out price estimates or quotes. The packaging industry consists of very complex and many variables that come into play. Below is a simple guide that will assist you in budgeting for your packaging costs.

The guide will offer you details of the type of costs to expect and how you can save money in your buying decision. It also includes a packaging box budget template that will guide you in your buying decision.

Contents

- 1 The Cost of Packaging Boxes

- 1.1 Raw materials

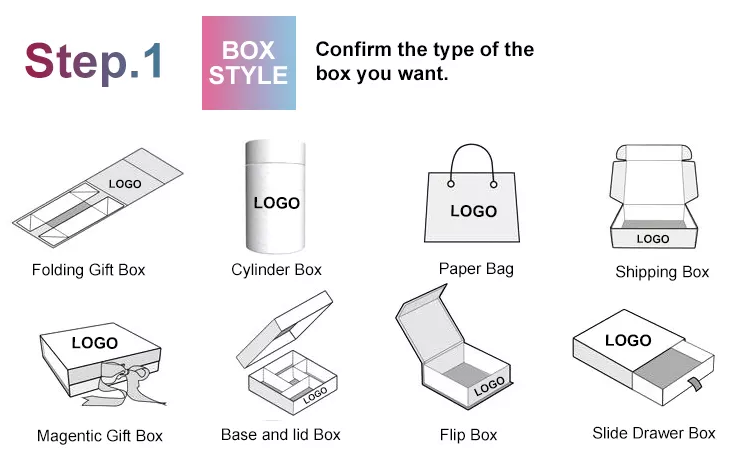

- 1.2 The Type of Packaging

- 1.3 Volume

- 1.4 Packaging Production

- 1.5 Transportation costs

- 1.6 Warehousing and fulfillment costs

- 1.7 Make packaging a priority

- 1.8 Streamlining inventory & economies of scale

- 1.9 Redesign packaging

- 1.10 Reduce labor costs whilst improving output

- 1.11 Use better equipment

- 1.12 Tailored sizes to avoid excess charges and void fill

- 1.13 Prevent returns and enhance customer satisfaction

- 1.14 Color Management with Advanced Printing Facility

- 2 Conclusion

The Cost of Packaging Boxes

Six main categories impact the packaging box’s price. They include;

- Raw Materials

- Packaging types

- Volume

- Costs of Production

- Costs of Transportation

- Costs of warehouse or fulfillment

The various pricing elements impact the final packaging box price. Moreover, they interact with one another to ensure complex pricing issues. For instance, the type of packaging influences the production costs for specific packaging types. If you compare folding boxes and rigid boxes, you will find that the cost of producing the rigid boxes is higher.

Raw materials

Raw materials are crucial for packaging production to take place. The primary raw materials necessary include;

- Glass

- Metal

- Plastic

- Paper (Wood)

There is a direct correlation between the cost and the number of raw materials manufacturers use to make a box. The higher the number of raw materials, the more expensive the packaging. The packaging industry, in most cases, has stable markets.

Thus, the cost of raw materials will most likely be constant. However, several factors, such as the recent pandemic, may affect the prices, and any shortages could increase the entire packaging costs.

The Type of Packaging

The type of packaging you need may influence the pricing significantly. For instance, moving boxes are much more expensive than single-layer plastic bags. The boxes need to be durable and sturdy to withstand the constant ups and downs during travel. Other boxes with higher prices include; rigid boxes, corrugated boxes, and folding cartons.

The boxes often have several layers that increase the protection level of the contents inside the box. Single-layer boxes are not so excellent for shipping. But are ideal for packing items such as cereals. However, shipping with single-layer packaging can be bad for the content as they can spill in transit.

Thus, the durability and sturdiness of the moving boxes make them more expensive. The trick, however, involves finding cheap moving boxes. But the best thing about these modern times is that you can always find cheap moving boxes near me.

Volume

The number of packaging units you order also impacts the pricing. If you choose to buy wholesale, you can save yourself some money. The more packaging boxes you order, the cheaper a packaging unit will cost. However, if you order a few boxes, the price per unit will be higher.

For instance, if the price of home depot moving boxes is 10 cents per unit at about 60,000 units. In addition, the price of 120,000 packaging units is 5 cents; you can note the pricing difference. The more you order, the cheaper the packaging box unit.

Packaging Production

Packaging production is another crucial element that influences pricing. Set-up fees and tooling costs are some of the essential aspects.

If you want custom packaging, a manufacturer will need printing plates and unique cutting dies to make your packaging personalized. The unique element necessary for customization is tooling, and you will have to pay for them separately.

In some cases, you may decide that you want to make changes in your box customization later. The key point to note is that you will need to pay more for new tooling. Furthermore, you can work with your packaging vendor to determine the right tooling and cost for your customization needs.

The set-up free costs refer to the costs needed for setting-up packaging manufacturing machines for your customized packaging needs. The more the machines and tools necessary for your custom packaging, the more you will most likely pay.

Transportation costs

The transportation costs involve any expense you use to ship your packaging from the manufacturer to the delivery point. In most cases, the transportation costs are very high as freight costs are always changing.

In some cases, shipping overseas is more expensive than buying overseas packaging. However, freight charges do not involve moving the packaging only. For instance, if you include special shipping instructions, you may need to pay for that. Thus, any special requirements ensure that your packaging needs will be more expensive.

Warehousing and fulfillment costs

Some cases may require you to order packaging and store them ahead of time. Some manufacturers will offer you the service, but at an extra fee; the fee may be large or small. You also may have a warehouse that is perfect for storage. But either way, you need to set aside extra funds for warehousing in your total packaging cost per unit.

If you want your products to be placed in the packaging, that is fulfillment, check with the packaging vendor first. The vendor may have logistics and other relationships with the fulfillment companies. The various relationships can help you save money.

Moreover, the fulfillment companies may hold the packaging inventory on your behalf, thus helping to eliminate the warehouse costs.

With increasing competition across practically every market sector, plus price pressures affecting everything from raw materials to logistics, companies must look at ways to reduce costs to remain competitive.

The packaging is no exception to this.

That is the utmost concern of each manufacturer or company to use the methods of manufacturing that provide their customers with fair rates. Customers have also become much sensitive about their products and their packaging.

For instance, if a person purchases a product of one dollar, he will never prefer to wrap packaging around it that is about the coats of 2 or 3 dollars. Thus, manufacturers keep in mind that what are the methods which preserve the rights and interests of both classes which are manufacturers and customers.

Make packaging a priority

As the manufacturing companies start to prepare the packaging options for various types of industrial products, they try to give priority to the products which have much space in the lives of the public. The products of the industry are preferred to manufacture. The upper preference of manufacturers is to prepare the medical as well as pharmaceutical products because of the rising importance of the products of medicine in the contemporary era. Thus, in the very initial stage, there is a dire need to prioritize your target audience as well the industry whose products are to be prepared by the company. When you will define your target audience, the target audience will be minimized automatically. After setting up the priority, you will be able to focus on the packaging methods which can be applied in order to provide customers with the best and most economic packaging for their products.

Streamlining inventory & economies of scale

One of the most commonly overlooked ways to reduce packaging costs is of packaging rationalization. By consolidating similar lines, your business can benefit from reduced costs thanks to leveraging economies of scale and streamlining your inventory.

Redesign packaging

The second method is the most important in this regard to provide fair and economic rates to customers regarding their packaging. The thing is to use existing designs with new and innovative changes. The old designs are required to mold with a new look and creativity. The methods and strategy to redesign the old designs will help you to not compromise on your manufacturing cost by offering the packaging options at economical rates. The previous products can be up grated by reducing the cost of the products. This aspect will help you to reduce the original cost of the products or packaging by more than 10 percent.

Minimize Packing Times

Reduce labor costs whilst improving output

Small gains in productivity can usually make a significant difference in your costs. By reducing spending on labor, being able to manufacture and ship more products, and fulfilling more orders, minimizing packing times can realize genuine cost advantages.

Use better equipment

Customers always seek to have the quality and variety for their products packaging. They want to have efficacy and multiple varieties in their packaging options. The manufacturers should understand this aspect and the desires of customers. Improving efficiencies in the packaging will help you to boost up the sale of your products. It will also corroborate to uplift the revenue of your company in multiple ways that will be definitely beneficial for you. The attention is to be given to the machines which are used for the preparation of the products. Advanced and modern technological machines are required to use for the manufacturing process.

Reduce Shipping Costs

Tailored sizes to avoid excess charges and void fill

Whilst usually a marginally higher unit cost, custom-sized packaging can soon pay for itself and should be seen as an investment rather than a cost. It eliminates shipping of “empty space”, which is particularly important with the increased use of volumetric shipping.

Prevent Damage In Transit

Prevent returns and enhance customer satisfaction

Transit damage is the hidden cost of your packaging. If items are not protected they can become damaged & unfit for sale. This incurs costs through returns, replacements & “written off stock”. Even worse, it can harm potential repeat business through dissatisfied customers.

Color Management with Advanced Printing Facility

Color management is very necessary as well as a primary thing in preparing a packaging option. The additional feature of printing is also based on the feature of managing coloring. The quality printing facility helps to make the look of the product attractive.

Conclusion

Packaging box pricing involves several factors. As you can see from above, different element combinations influence the final packaging pricing. Thus, the above will help you know how to budget your packaging needs and what to expect from manufacturing to packaging delivery.

By Sofier Ju

By Sofier Ju